In the past 5 years

the aftermarket industry has put out newer and more exciting suspension kits for

cars and trucks alike. From, BWM to Ford, whether it be a coilover setup, race

springs, sway bar, most customers will find what they need. With the

introduction of parts that make suspensions more adjustable than what the end

user is capable of tuning, we come upon a newer market of Camber kits/Alignment

kits. In this article we will be going over an install of the Skunk2 upper

control arm camber kit for certain Honda made vehicles.

The newer breed of

camber kits are using adjustable ball joints to get the job done. The first on

the market with the concept was Kmac of Australia, their idea soon became a

popular one and other companies quickly developed different techniques to employ

adjustable balljoints into their components. After reading and listening to the

buzz about this kit, we decided to pick it up and try it out, on a 1998 Honda

Civic. I had installed and tested almost every type of kit available for this

type of car. This left me with a good idea on what I needed and what I did

not.

The beauty of waiting a

while before ordering new parts is to have the abilty to do some research on

what other tuners like and disliked about them. In the case of this part, there

was a huge concern about two major failures with this kit, both which I was

ready to address both during and after the install.

I started the process by

ordering the parts through Matt M. (MatT3T4 on Hondavision.com) through his own

company Speedupgrade.com. He was able to beat the lowest prices on the net for

this kit. I recieved the kit within 7 days and no problems were

noted.

I prepared the install by

getting the proper tools together, which included 8-17mm wrenches and sockets

with a 3/8" drive and a 3/8" Tq. Wrench. I also had some zip ties for supporting

the knuckle once dislodged from the ball joint. For this install it was also

required to buy a 5mm 3/8 socket allen key to lock down the allen nuts on the

camber kit. See Image 1a. In addition I was prepared

for the problems that seemed to plague many people's installs. I brought along a

spray bottle of 303 Aerospace Protectant, as well as some industrial silicone

grease made by ShinEtsu and some thread lock compound. I will explain their use

later in the article. See Images 1b.

After the preparation was

finished I headed to the garage with some portable jacks and jackstands, and

began to support the vehicle. After removing the wheels, I began the process of

removing the cotter pin from the castle nut and the castle nut from the upper

ball joint.

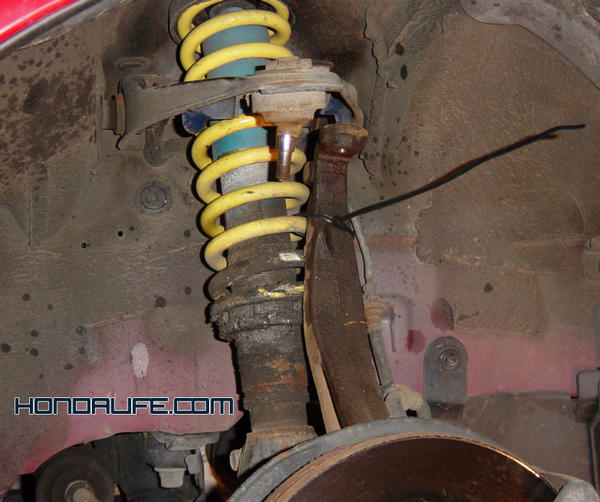

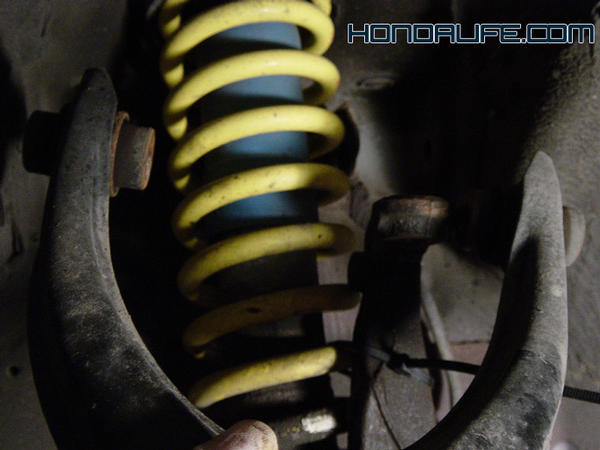

In the case of this removal,

the control arm being removed was a modified OEM arm with a Kmac camber plate

with floating ball joint. The ball joints were worn out on that kit. After

removing the castle nut we carefully separated the knuckle from the ball joint.

Some peeople may need a ball joint separator which we did not need. After the

knuckle dropped we zip tied the knuckle to the coil spring to avoid any possible

damage to the lower suspension components.

Now that that the knuckle

was separated we just needed to remove the existing upper control arm. The

1996-2000 Honda Civic arm is the only kit where the arm actually uses its own

pressed in bushings.. This is because the bolts mount through the arms to the

sides of the shock tower vs. the top on the Integra, Del sol and the 1992-1995

Civic. After opening the hood we located the bolts holding the arm on. We

decided to remove the battery to get at one of the bolts which was not needed

but helped. After removing the bolts we were able to dislodge the

arm.

Before installing the Skunk2

arm I soaked a towel with 303 Aerospace Protectant and sprayed and wiped the

protective boot. It already had a coating on it however this was just a bit of

added protection during the install. If it is winter or if the temperature is in

the 40 degree range or below apply ShinEtsu to the boot using gloves. In

addition, we loosened all of the allen screws on the control arms so the ball

joint was free to slide. We then mounted the control arm. We replaced the bolts

holding the control arm to the sub frame but did not tighten them down to

factory specs yet because the knuckle was not re-attached yet, nor was the car

lowered back down onto the arms.

After we had

things ready we cut the zip tie and pulled the knuckle up to the main bolt on

the control arm, making sure the knuckle was as flush with the balljoint as

possible. We installed the new castle nuts supplied as well as the cotter pin

and tightened it down to factory specs. Now that we had that done,

we preped the torque wrench and attached the 5mm allen key and set the

ball joint in the middle of the grooves. This was just a temporary spot being

that the car would need an alignment after this install. We went with 10lbs of

torque since there was not a solid recommendation, however when we

tightened it down to that spec the force crushed and pushed out the locking

washer a bit so we decided to drop it down to 8lbs/ft.

We completed the same

procedure on the other side, after everything was was set we reinstalled the

wheels and lowered the car down, and tightened the control arm bolts under the

hood down all the way to factory specs.

Since I was not satisfied

with the way the kits allen screws tightened down I contacted Skunk asking them

why they don't have some type of torque instructions for these kits. And related

stories I had heard about the ball jount sliding out of place under race

conditions, which would be a disaster.

The following email

ensued.

Dezoris to Skunk2

The major

problems we have seen, is the rubber boot cracking, as well as the allen nuts

coming loose.

So I called your contact number which the gentleman on the

phone gave me some general answers but not what I was looking for. I was told to

email you.

So here they are.

1.)What type of material is the

rubber boot made from, no one seems to know. There was some mention that it was

EPDM rubber, while others thought it was Urethane. Regardless I am looking for a

way to protect the boot from cracking, so knowing the material is half the

battle.

2.)Allen wrench screws. What size tool do the screws

take?

3.)Tq, How much to Tq, the nuts. I understand they are

self-locking. But what is a reasonable Tq level.

This is a major concern for

Autoxers.

I appreciate your time

Sincerely,

Mark

Sanew

SKUNK2 to

Dezoris

Hello

Mark,

Thanks for your interest in our product. In response to your

questions-

1.) The boot is made of rubber.

2.) 5mm Hex-Head The bolts are

a tyical Honda size- M6x1.0x15mm

3.) The bolt comes with a washer and a lock

washer, some people have used larger washers to increase clamping area. 12 Ft

Lbs is an acceptable torque spec for these. Of course if people are seeing

issues of bolts loosening they should use an acceptable thread locking compound

for their situation.

I hope this helps you out.

Best

regards,

Chris

Dezoris

to Skunk2

I used a tq.

wrench using 10lbs and I crushed and pushed out the locking washer below the

bolt head.

So I went down to 8lbs on the rest and it seemed to be just

right. 8lbs is not much thread lock would be smart, as well as the larger

washers to spread out the pressure on the arm

I will forward

you my review when I am done with the article. Is it ok if I use the information

you provided in my article?

Skunk2 to

Dezoris

Huh, that is

weird. I lust torqued down all 4 screws on an arm and had no issues of upsetting

the lock washer. I would suggest 8lbs WITH threadlock.

I would like to see

the article when completed, and yes, you may use the info we

discussed.

Thanks,

Chris

So that email took place

partly before and after the install. I needed to get some thread lock on those

bolts, so I called King Motorsports to schedule an alignment. On the phone I

mentioned I needed to get an alignment and corner weighing due to my

suspension and the gentleman on the phone was unable to accommodate me.

Without going into the details of this annoying experience I have since worked

it out with Clayton at King. He and I worked out my issues to see that

I did not carry an bad opinion or have a bad image of King

Motorsports, which I appreciate. But back when I needed their services I was

turned away which took me to Big Bear Tire in Wisconsin. They were able to get

me in for a full corner weighing and alignment within a week, which, my initial

request was a month. Needless to say they applied the thread lock torqued the

bolts to 8lbs/ft and really spend some time with my car and with me making sure

that the alignment was best practice as well as the corner weighting. It was

some of the best customer service I had ever had from a shop, that did race

services.

Moving forward well over a

year later taking the precautions to keep the kit in good shape has paid off,

through rain snow and countless autocrosses and alignment the kit has stayed

true, problem free. No problems with the ball joints, protective boots or

slipping of the allen locks. Not bad for a daily driver weekend racer.

PREVENT THIS

WITH TIPS BELOW

I like the kit, because I

have not had to replace it for failure. I think this is largely because of the

maintenance performed on it. Is maintenance on a camber kit a bad thing? Not in

my opinion, for a few major reasons. Most people with the cars these kits are

designed for are going to be daily driven, which will see a variety of harsh

conditions. Other suspension components require similar care, such as bushings

and threads on adjustable shocks. These parts need lubing namely if driven in

the winter to avoid binding. If other parts need it, then it is completely

acceptable to add another part to the list to care for.

I don't like the kit because

of the locking washers and allen adjusters. They are not heavy duty enough, to

be confidence inspiring, and requires special install to make sure they won't

slip. Another downfall is that the kit cannot be adjusted under load. The car

must be raised and lowered everytime an adjustment is made. Which may not seem

like a big deal, but try asking your average alignment shop how they like that?

This however is a lead in to another positive aspect. The kit is a no brainer to

adjust, there is no room for error unless it is over or under tightened. The end

user can take to it most alignment shops and not have to draw out a diagram on

how the part works.

In conclusion this is a good

product that could be great with slight changes in the manufacturing

process.

TIPS!!!!

If the car

is daily driven in a variety of climates:

Apply coat

of 303 Aerospace Protectant to boots in Summer every month, if possible. Every 3

months at the max.

Apply

ShinEtsu G-3W-0 Silicone Grease to boots before fall. Re-apply when

applicable.

Apply Thread Lock to allen screws before each alignment to keep the plate

on the kit from coming loose. Or use bigger washers to secure the allen screws

to the arm.

Dezoris - M.

Sanew

Thanks to:

303 Products - Big Bear Tire - ShinEtsu

http://www.speedupgrade.com

http://www.hondavision.com

http://www.skunk2.com